Signed in as:

filler@godaddy.com

Signed in as:

filler@godaddy.com

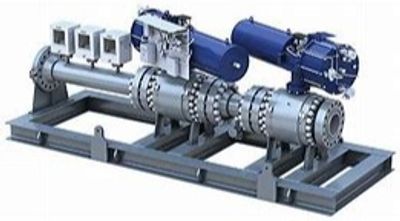

High Integrity Pressure Protection Systems (HIPPS) is designed to reduce the risk if the pressure of a system exceeds its design pressure. With today’s requirements for higher flow rates and pressures, the ability to lock-in pressure using a performance-based, non-descriptive framework and life-cycle data is required. These systems include emergency shutdown valves, pressure sensors, fail safe actuation, partial-stroke testing and a logic solver—all with built-in redundancy in a skid-mounted package.

HIPPS systems are used in the oil and gas industry, LNG facilities and transport and storage systems to ensure the safety of pipelines, piping, vessels and process packages. Regardless of what application, any containment loss due to over-pressurization is a critical issue.

HIPPS is an instrumented safety system that is designed and built in accordance with the International Electro-technical Commission (“IEC”), IEC 61508 and IEC 61511 standards. These international standards refer to safety functions (SF) and Safety Instrumented Systems (SIS) when discussing a solution to protect equipment, personnel and environment.

A system that closes the source of over-pressure within 2 seconds, with at least the same reliability as a safety relief valve, is usually identified as a HIPPS.

-0001.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:600,h:300,cg:true)

MFC HIPPS is applied to prevent over-pressurization of a plant or pipeline by shutting off the source of the high pressure. The MFC HIPPS totals over 35 000 (with over 2500 valves) operational years and are therefore proven-in-use for high reliability safety applications.

MFC HIPPS is a type of SIS designed to prevent over-pressurization of a plant, such as a chemical plant or oil refinery. MFC HIPPS will shut off the source of the high pressure before the design pressure of the system is exceeded, thus preventing loss of containment through rupture (explosion) of a line or vessel. MFC HIPPS is considered as a barrier between a high-pressure and a low-pressure section of an installation.

We have a specific brochure for this HIPPS products. Download it from the link below.

Files coming soon.